So there is alot of buzz about our modified 99mm K24 crankshaft kits going into an H series block. One of the most common questions is “What rod and piston combo do I use?” The best answer I feel is custom for both, though there is an OEM option. We will discuss the pro’s and con’s of it and hopefully if you are new to engines you will learn a thing or two along the way. Of course if you are just starting to learn about this sort of thing I do not recommend trying to order these parts yourself, but rather look to one of our dealers to put a whole crank/rod/piston package together for you. The main goal of this post is for you to simply be a more educated consumer and understand what goes into some of this process. Before we get too far into it lets go over some basic terminology you will encounter when dealing with this sort of thing.

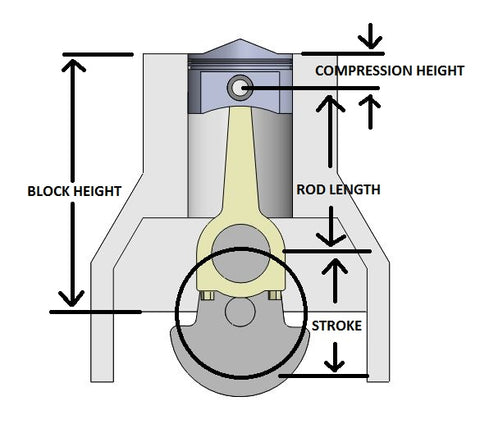

Stroke: Stroke refers to the throw of the crankshaft, or the total distance it moves up and down. This also directly relates to how far the piston moves up and down so you can also think of it that way.

Main Journal: This is the journal of the axis of the crank, on an H series there are 5 “main” journals and on the K24 crank the journal size is 55mm.

Rod Journal: This is the journal of the crankshaft that the rod rotates around. The K24 crankshaft rod journal is the same diameter as an H series crank however it is much narrower (and an H rod will not fit).

Block: This is an easy one so I won’t even bother.

Main bore: This is the term used to describe the main bore of the block that the crank rotates inside of. More often than not however, especially in the H series world, this describes the main journal diameter of the crank. In the case of this K24 crank it is 55mm. When you add in bearing thickness the physical bore of the block is actually several mm larger.

Block Height: I have heard this expressed a few different ways but the method I have always used, and the method I will use in this instruction means the distance from the crankshaft centerline to the top of the block. If you have ever “decked” your block, this number will change, and it is important to know when designing a custom rod and piston.

Rod Length: Rod length is expressed as a center to center distance, the distance from the center of the big end of the rod to the center of the small end of the rod.

Rod Big End: This term refers to the inside diameter of the connecting rods “big end” and is important when designing a custom rod, or searching through catalogs trying to find a shelf rod that will work.

Big end width: The width of the connecting rods “big end” This needs to be a specific size in order to fit the rod journal of the crank.

Rod small end: This term refers to the nominal diameter of the small end of the rod and is also the size of the corresponding wrist pin. The width of the small end is generally the same as the big end width, but not always.

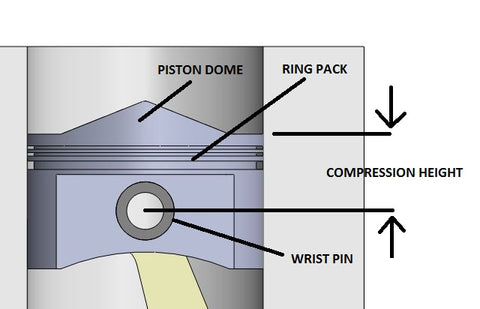

Wrist pin: The wrist pin is the interface between the rod and the piston. It is specified by its diameter and it allows the rod and piston to pivot with each other.

Compression Height: The compression height of the piston is the distance from the center line of the wrist pin to the flat part of the top of the piston (not the top of the dome) This is one of the main dimensions we will be dealing with when preparing to order a custom piston.

Piston CC: This is a measurement of the dome (or dish) of the piston. It is the volume of material that sticks out from the top of the piston (or the dish of material below). It can also be the sum of both, which it is on any piston with valve reliefs and a dome. Say the physical volume of a dome sticking up above the compression height is 6cc, but the piston has 4 valve pockets that would be a 1cc “dish”… the 1cc dish is subtracted from the 6cc dome and the piston is said to have a 5cc dome. This number is one of the big factors which determines overall compression of the engine.

Ring Pack: These are the piston rings, normally 3 and also a limiting factor in how short you can make the compression height of a piston. If the compression height is too short then there isn’t enough distance between the wrist pin and top of the piston to adequately fit the ring pack. In some racing applications racers will do without oil rings, or install them across the wrist pin bore and use supports or buttons. There is a few ways to do it, we won’t get into the discussion on what is best but its something to be aware of.

Clear as mud?? If you are new to engines this can be a lot of information to take it. It is also sometimes difficult to explain in words. I’ve put together the following illustrations to help make a bit more sense of it.

Ok, now that we have that out of the way lets start talking numbers. When running the K24 crank in an H series block we need to calculate an appropriate length connecting rod and appropriate compression height of the piston so that the piston does not protrude ridiculously out of the block, nor is it sunk too far into the block when at top dead center. For this calculation we will shoot for getting the top of the piston flush with the top of the block. Since the crank is a K series, everything to do with the rod’s “big end” will be identical to the dimensions of a typical K series rod. Since the H series and K series use the same wrist pin diameter, all we really need to do is change the length of the rod itself. All else to do with the rod will be the same as a typical K series rod. Why can’t you just use an off the shelf K series rod? You can, but we will get to that later. On the piston side of things you will want to have a piston designed similiar to any other shelf H piston, the only thing that will really get changed is the “compression height” dimension.

Lets start with what we know:

The block height of an untouched H series block is 8.643″

The stroke of a K24 crankshaft is 99mm, or 3.897″

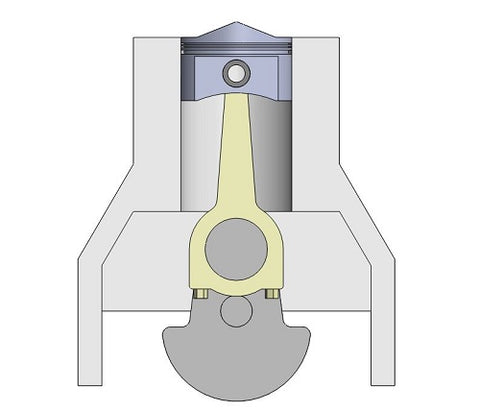

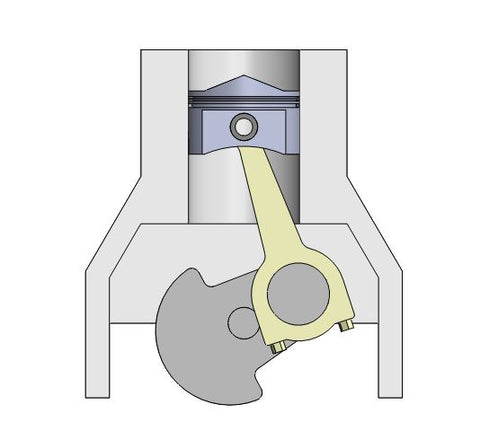

In order to come up with a rod and piston combo that leaves the piston sitting flush with the deck of the block we need to do some math. The best way to think of how this all works is to look at the illustration below with the piston sitting at Top Dead Center or TDC.

Since we know that the block height is 8.643″ and we know that half of the stroke of the crank is 1.948″ we can determine that the total length of the rod plus the compression height of the piston needs to be 6.695″ (8.643-1.948=6.695).

Now lets talk about the rod for a bit. Ideally we want the rod to be as long as possible. The longer rod creates less of an angle as the piston moves up and down the cylinder and prevents a thing called “side loading”. You will also hear a term called R/S or rod to stroke ratio. Basically the higher you can get this ratio the better. You want to use the energy of the combustion process to move the piston down the cylinder as efficiently as possible. Having a longer rod compared to a shorter rod transfers more energy into the crankshaft and therefore makes more power. It creates less of an “angle” between the rod and crank. There is much debate out this factor and I won’t go any further on it, but I think that the general consensus is if you can go after a better R/S ratio then why not? Especially since we are talking about custom rods and pistons, you might as well take advantage being able to alter this in your favor.

The limiting factor in designing the rod length is the other variable in our equation, the compression height of the piston. Being that you want the rod length as long as possible this also means that you would want the compression height of the piston as short as possible. I will assume that everyone here will be running a standard 3 ring pack, two compression rings and an oil ring however thats not always the case. Some racers choose to run only one compression ring and some have also eliminated the oil rings. It all depends on what you want to use the piston for and how long you want it to last. For this equation we are going to keep it simple. From experience I know that a 1.140″ compression height is getting close to the limit to where you either have to start eliminating rings or go with a button type or support rail type setup where the rings are passing over the bore of the wrist pin. Again we will keep this simple and use the common 1.140″ compression height.

Since we now have our piston compression height, we can subtract that from the number above. 6.695-1.140=5.555″ and that is our rod length!

In short, you will need a custom K series rod with a length of 5.555″, and a custom H series piston with a compression height of 1.140″. Here is an example of what that setup would look like:

Of course there are several ways to do this but keep in mind if you change the length of the rod you will need to compensate by changing the compression height of the piston and vise versa. For best results speak with one of our dealers about putting together a complete package for you that fits the needs and goals of what you are trying to accomplish.

Oh yeah.. The OEM Option: The OEM option using factory off the shelf parts consists of using a K20 connecting rod and an H series piston. The downside to this is that the K20 rod is very short. It would work, but its definitely not ideal and isnt going to be the high rpm monster you were hoping for. Expect lower peak power, increased piston wear, and overall reduced life from this setup. I figure if you are the kind of racer looking to spend the money on this type of setup then you most likely aren’t going to cheap out and use factory parts, BUT it is another option.